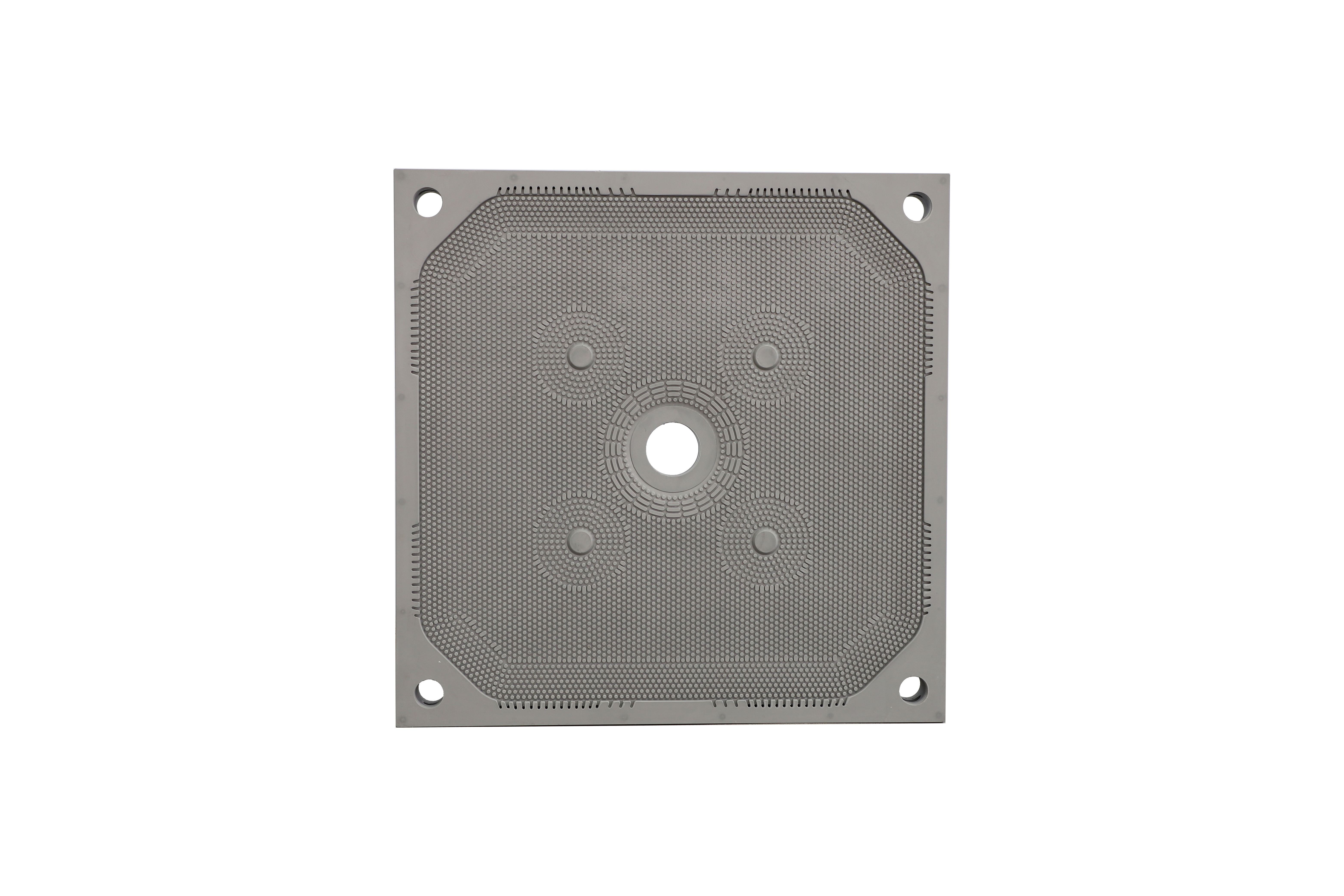

LVPA20 Filter Plate

Our company is a professional distributor of well-known domestic and foreign filter presses and related products.

Keyword:

NADZIA

Category:

Tel:+86-15166989872

E-mail:sales@nadzia.net

Product Description

PP Filter Plate

We use pp material to press mould, and the design of filtration surface adopts special channel, smooth and without any blockage. Material of plate consists of TPE elastomer, fiber glass, and Polypropylene. So our plates have the advantage of flexibility, toughness, rigidity. After the process of the CNC machining center, the flatness of the filter plate is lower than 25µm which make sure excellent sealing when pressing, and without any leakage when feeding.

Compared with the filtration plates manufactured according to national standards: filtration speed improved 20%, density and intensity, anti-fatigue, anti-aging.

The maximum feeding pressure of the filter plate is 1.6Mpa. With the properties of high temperature and high pressure resistance, antisepsis and airtight, short filtering cycle, good processing effect and low humidity of the cake.

Chamber plate

We developed various filtration plates with all kinds of specifications and shapes.

We have plates with material of cast iron, steel Q235,cast steel, stainless steel, cast copper, aluminum alloy, pp, TPE elastomer, EPDM, NBR and etc.

Max Feeding Pressure 3 Mpa.

Futures: High Temperature and high pressure resistance, excellent sealing and cake washing, anti-corrosions, short filtration period, lower cake moisture.

Membrane plate

Membrane plates bring superexcellent filtration effect and unimaginable benefits.

Solid content can be controlled by squeezing pressure.

Squeezing twice after completion of filtration can improve solid content of the cake.

Membrane plate can carry out “Low pressure for filtration, higher pressure for squeezing.” Improving life-span and reducing energy consumption.

Product Illustration

Supply Ability

5000 Pieces per Day

Packaging & Delivery

Packaging Details:wooden box and plastic film to prevent ultraviolet ray

Port: Tianjin ,Qingdao or customer specified

Lead Time

7 days

We Offer

1.to supply operation manual of filter press and filtration elements which introduced the specifications and Warnings.

2.to optimize the technical data of filtration and constitute operation regulations for customers accordingly.

3.to supply the filtration flow chart according to different material and demands.

4.to find out the most suitable technial data(time,pressure,cake thickness,capacity of washing water).

5.the filtration testing free of charge.

6.methods for treating with abnormal conditions

7.installation and commissioning

8.trouble-shooting

Previous page

Next page

Product Consultation